Servo motors are an essential component in many electronics projects, offering precise control over rotation. When integrating servo motors with ESP32, it’s vital to follow safety precautions to avoid damaging your board or the servo. Servo motors, especially continuous and high-torque types, can draw significant current, posing a risk to the ESP32’s delicate GPIO pins and power supply. Understanding how to set up your servo motor correctly will save your components from unnecessary wear and tear.

The ESP32 is a versatile microcontroller ideal for handling PWM signals needed to control servo motors. However, its 3.3V logic level and limited power output mean that proper planning is necessary when interfacing with servos. In this guide, we’ll explore best practices for safely connecting servo motors with ESP32, from wiring considerations to essential protective measures.

Understanding Servo Motors with ESP32

Servo motors are often used with ESP32 in robotics, home automation, and prototyping due to their ability to perform controlled movements. However, improper handling of power, connections, or code can result in malfunction or permanent damage. The ESP32, while powerful, has limitations in handling high current and voltage requirements that servos sometimes demand.

To start, always verify the servo motor’s specifications and ensure they align with the ESP32’s capabilities. A standard SG90 servo, for example, operates at 5V and can draw significant current under load. While the ESP32 can provide a PWM signal to control the servo, it’s often insufficient to power the motor directly.

Safety Precautions to Follow

- Use an External Power Source Avoid powering the servo motor directly from the ESP32’s 3.3V or 5V pins. Instead, use a dedicated external power supply to provide stable power. Connect the servo’s ground (GND) to both the ESP32 and the external power supply to ensure a common ground.

- Add a Flyback Diode Servo motors can generate back EMF (electromotive force) during operation, which may damage your ESP32. Installing a flyback diode across the motor terminals can mitigate this risk by safely dissipating the reverse current.

- Include a Capacitor for Voltage Stabilization A capacitor connected across the power supply can smooth voltage fluctuations caused by the servo’s sudden power demands. This stabilization prevents erratic behavior and protects the ESP32 from voltage spikes.

- Limit Current with a Resistor or Dedicated Driver Circuit If your servo motor draws more current than the ESP32 can handle, consider adding a resistor or a motor driver circuit. These components help manage current and prevent overloading the ESP32’s GPIO pins.

- Test Your Connections Carefully Double-check all wiring before powering your system. A short circuit or incorrect wiring can damage both the servo motor and the ESP32. Use a multimeter to verify connections and test voltage levels.

Wiring Diagram for External Power Sources

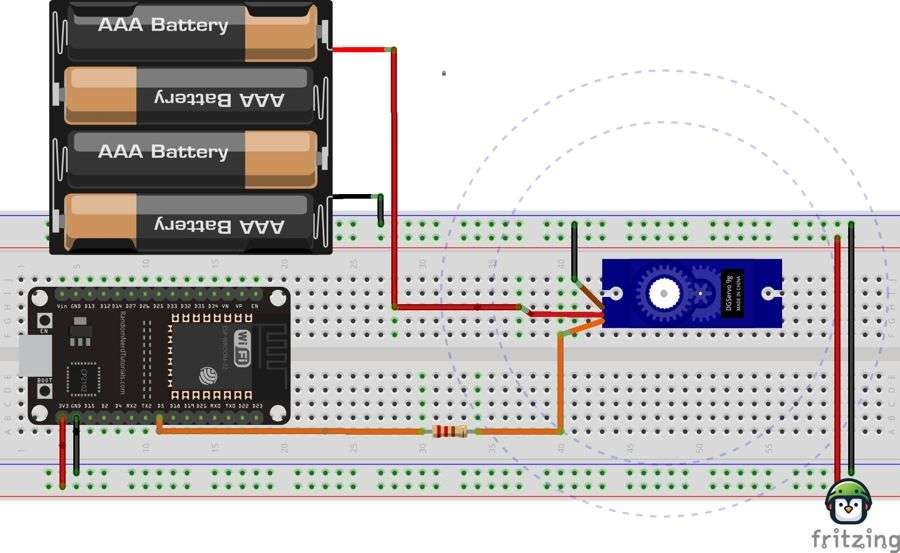

Below is a wiring diagram illustrating how to safely connect an external power source to a servo motor controlled by the ESP32:

Diagram Description:

- ESP32 Connections:

- Connect the GND pin of the ESP32 to the GND rail of the breadboard.

- Connect the PWM GPIO pin (e.g., GPIO18) to the Signal pin of the servo motor using a 220-ohm resistor.

- Servo Motor Connections:

- Connect the servo motor’s GND pin to the breadboard’s common GND rail.

- Connect the servo motor’s VCC pin to the +5V power rail from an external power supply.

- External Power Supply:

- Connect the external power supply’s GND pin to the breadboard’s common GND rail.

- Connect the external power supply’s +5V pin to the +5V power rail on the breadboard.

Key Notes:

- Ensure a common ground between the ESP32, servo motor, and external power supply for proper signal communication.

- The 220-ohm resistor between the GPIO pin and the servo’s signal pin helps protect the ESP32 from potential current surges.

- Optionally, add a 100µF capacitor across the power supply rails near the servo motor to stabilize voltage.

This setup ensures reliable operation and protects the ESP32 from electrical issues when controlling servo motors.

This setup ensures that the servo motor receives adequate power without overloading the ESP32. The common ground is crucial for the proper operation of the PWM signal.

Common Questions

- Is it correct to attach a common ground from both 3.3V and 5V sources? Wouldn’t that damage the board? Yes, connecting a common ground is essential for the circuit to function correctly. It does not damage the board as long as the ground is shared properly and the power sources are isolated for their respective components.

- I read somewhere that it is good to attach a resistor to the signal pin. Would this help? Adding a small resistor (e.g., 220 ohms) to the signal pin can protect the GPIO pin from potential current surges and noise, enhancing overall reliability.

- If the servo is powered via external sources, would this isolate the board from EMF? While using an external power source reduces the load on the ESP32, it doesn’t fully isolate the board from EMF. Adding a capacitor and flyback diode can further minimize EMF interference.

- Recommend the right rating for the capacitor for voltage stabilization. A 100µF to 470µF electrolytic capacitor is typically sufficient for most servo motors. For additional stability, you can pair it with a 0.1µF ceramic capacitor.

Resources

For a detailed guide on setting up PWM signals with ESP32, see our article “Using PWM with ESP32 for Precise Control”.

For servo motor specifications and advanced configurations, refer to the manufacturer’s datasheet.

Conclusion

When working with servo motors and ESP32, taking the necessary precautions ensures a safe and successful project. Servo motors are highly versatile, but their power demands can quickly exceed what the ESP32 can handle without proper safeguards. By following recommended safety practices, such as using an external power source and stabilizing voltage, you can protect your hardware from unnecessary damage.

Integrating servo motors with ESP32 opens up a world of creative possibilities in robotics, automation, and DIY electronics. With careful planning and adherence to safety guidelines, you can make the most of your projects while keeping your components safe. For more resources on microcontroller safety and project ideas, explore our ESP32 project hub.

Leave a Reply